Steel Slag Processing Plant

Processed material: steel slag

Production capacity: 60-1000 t/h

Main equipment: jaw crusher, cone crusher, rod mill, autogenous mill, and vibrating screen, etc.

Where to use steel slag?

Steel slag is applied to road construction, metallurgical use, fertilizer, cement concrete addition, ans steel slag brick.

Steel slag contains reactive minerals like tricalcium silicate, dicalcium silicate and ferro -aluminate, which are similar with the cement contends that are featured with hydraulic cementing materials. Meanwhile, steel slag gravel has the features of high density, high strength, rough surface, stable characteristics, wearable and long lasting, easy and fastens to mix with pitch.

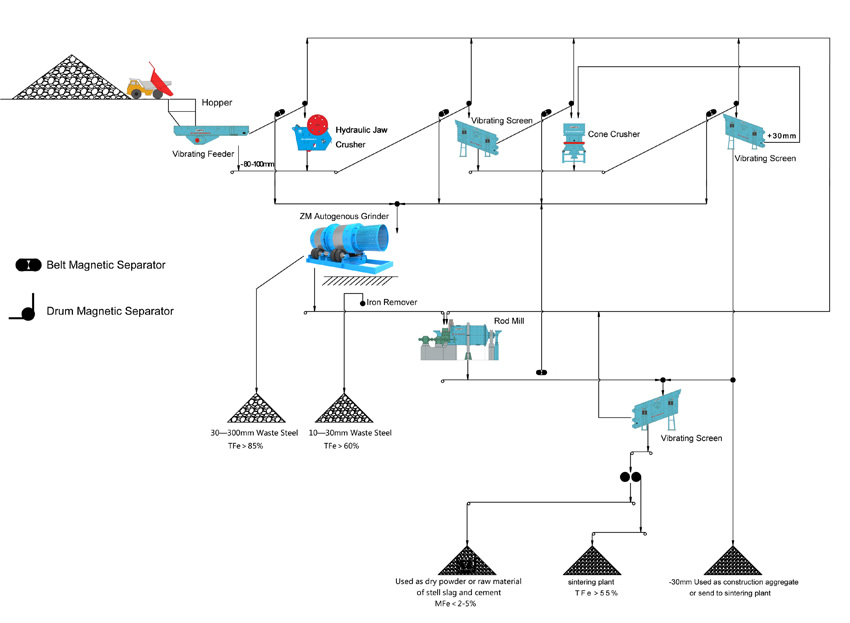

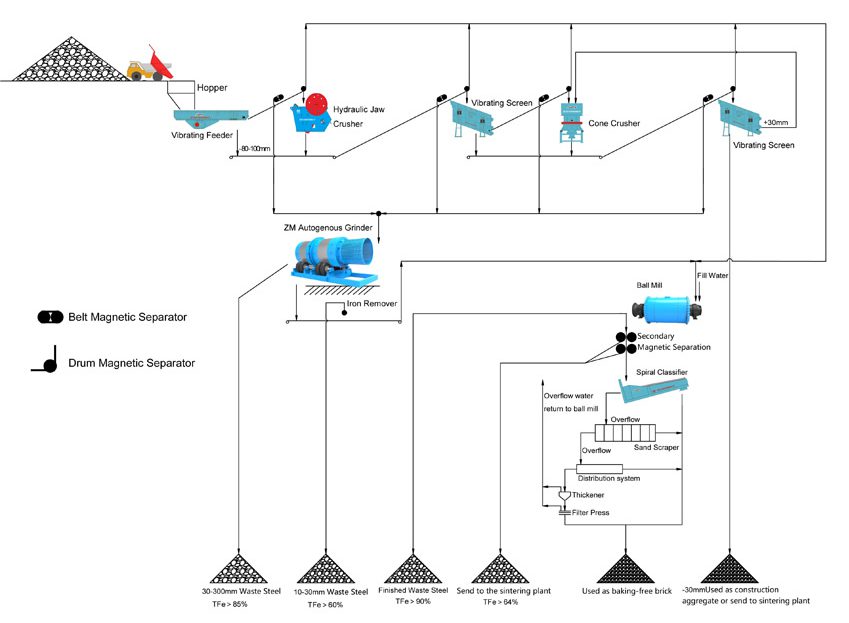

Production Procedures

Luoyang Dahua had developed “Dry method” and “Wet Method” comprehensive recycling equipment respectively. The production capacity is 60-1000 t/h. We provide high efficiency, energy saving techniques and equipments for steel slag recycling plant to achieve the aim of steel slag zero emission and building up sustainable development, energy saving enterprise.

Process Features

★ Standardization:

The steel slag production line adopts a European standard design. The overall process layout is more compact, standardized, and rationalized.

★ Standardization & Modularization:

The entire production line equipment can be assembled on-site. This approach reduces construction time and ensures convenient and reliable installation and operation of the production line.

★ Intelligent:

The production line is equipped with an intelligent control system, including cloud monitoring system, DCS system, and intelligent metering system.

★ Environmental Protection:

The whole production line is equipped with dust removal facilities to ensure a dust-free production site.

Related Products

WHY CHOOSE US

Luoyang Dahua Heavy Industry is a joint-stock professional enterprise which is integrated with R&D, production, sales and service. As a high-tech enterprise, we focus on the design of crusher and grinding equipment, sand aggregate production lines, automation control schemes, civil engineering projects and also provide project installation, overall system operation and delivery.