Hot

PRODUCTS

60

+ Years

Experience of

crusher manufacturing

100

+ Engineer

French Technology

Japanese Technology

78

+ Patents

ISO Certificate

CE Certificate

Customer

CASES

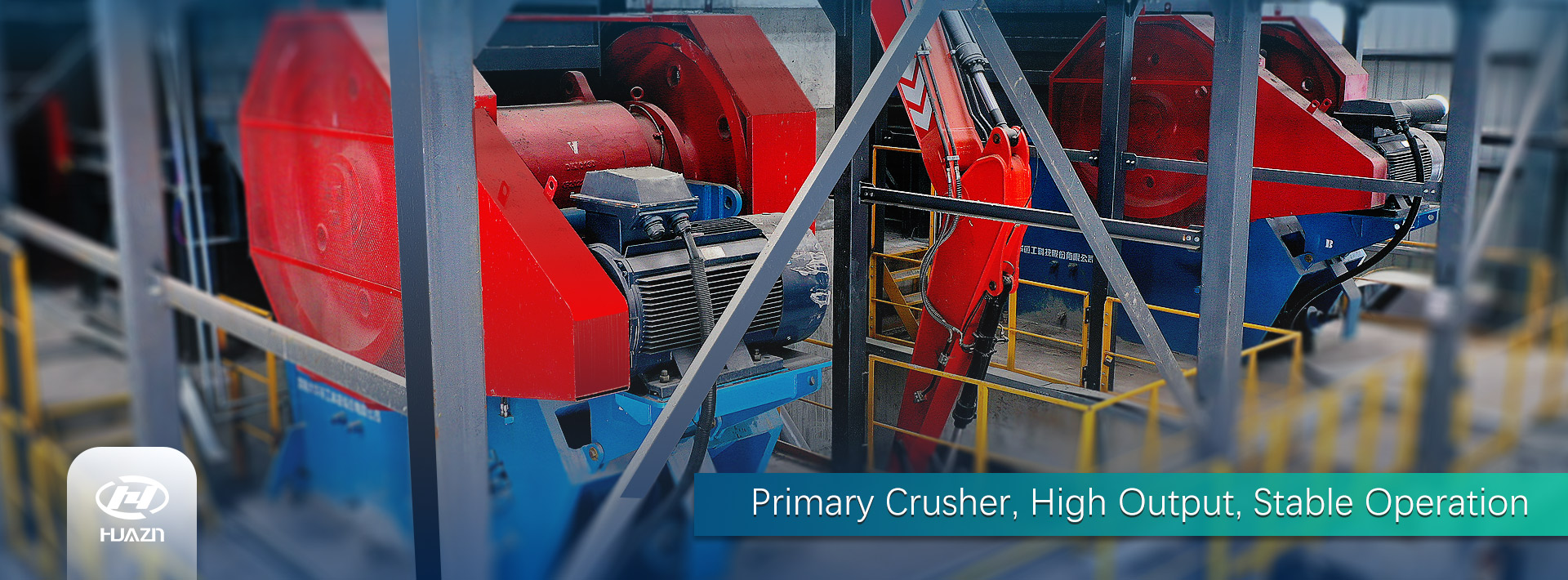

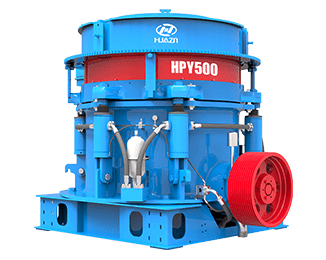

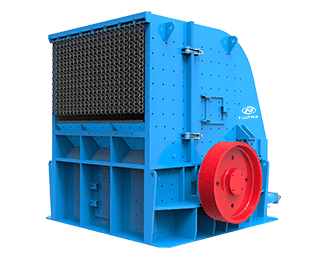

Focusing on the R & D and manufacturing of crushing and screening equipment, we provide complete set of crushing and grinding equipment solutions

100 t/h Stone Crushing Production Line for Hydropower Station in Nepal

This 100t/h project is located in Nepal for hydropower station construction.

90t/h Sand and Stone Wastewater Treatment System for Hydropower Project in Pakistan

This 90t/h sand and stone wastewater treatment system is designed for hydropower station in Pakistan.

600t/h Limestone Crushing Project in Saudi Arabia

This project is located in Saudi Arabia for limestone crushing. The core system and functions have been optimized and adjusted to withstand…

450 t/h Crawler Mobile Jaw Crushing Station in China

This crawler type mobile crushing station is applied for the olivine crushing, which is mainly composed of jaw crusher and vibrating feeder.

100000T/Y Steel Slag Treatment and Recycling Production Line

The project is 10000 t/y steel slag treatment and recycling production line.

2000t/h EPC Project for Limestone Crushing Production in Anhui, China

This EPC project is for limestone crushing production with capacity of 2000t/h in Anhui, China.

Latest

NEWS

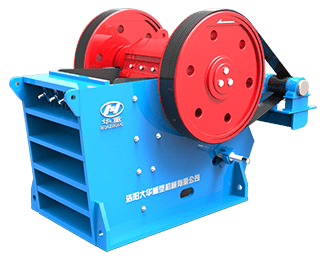

Reason and Solve Method of Material Blocking in Jaw Crusher

Feed blocking is one of the common problems of the jaw crusher. It directly affects the normal operation and greatly reduces the production efficiency. Luoyang Dahua Heavy Industry will talk…

The Influence of Rock Physical Performance on Crushing Machine Production Rate

The influence of rock physical performance on crushing machine production line mainly on below points.

Reason of Uneven Discharge Granularity Size of Jaw Crusher

When the swing jaw goes up, the materials are crushed, when the swing jaw goes down, the crushed materials are discharged by gravity. The uneven granularity size often appears during…

Roll Crusher Maintenance and Test

The roll crusher can handle both primary and secondary crushing, making the rock, coal suitable for various applications in mining, quarrying, and recycling industry. What is the maintenance and how…

Which Machine is used for Steel Slag Processing?

Steel slag is a byproduct of steel production, with high hardness and strong wear resistance. When selecting the steel slag crushing machine, we need to consider the material characteristic, processing…

Introduction of Small Jaw Crusher

Small jaw crusher is a kind of mechanical equipment for coarse or medium crushing of hard materials, suitable for small mines, construction sites or recycling industries. The following is the…

Hot Crushing Equipment for Limestone – Jaw Crusher

Limestone is widely used in construction industry, while its fineness becomes the primary concern for the customer. In modern production, the main equipment to produce limestone is jaw crusher.

How to Treat the Waste Water in Mineral Separation

There are lots of suspended solids, medicament, heavy metal ion and etc. in the waste water of mineral separation. If they cannot be treated by means of scientific and reasonable…

Good Maintenance Prolongs the Service Life of Stone Crushing Machine

Service life of stone crushing machine is determined by the machine quality and the right operation and scientific maintenance. Especially the maintenance, only we take a good maintenance, the longer…