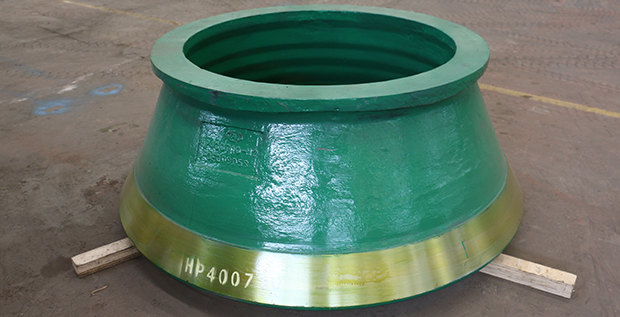

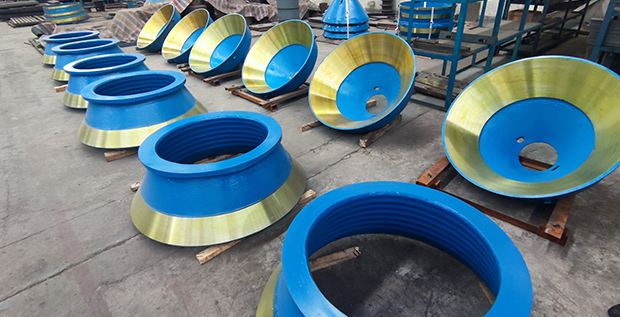

Cone Crusher Mantle Concave

Poduct type: cone crusher mantle, cone crusher concave

Application:

mining, quarry, cement for crushing hard and medium hard ore and rock

Customizable: Yes, based on drawings or samples

Tel.: +86 13938852499 E-Mail: [email protected]

PRODUCT INTRODUCTION

Mantle, concave, bowl liner are the main wearing spare parts for cone crusher. Luoyang Dahua is the professional supplier for crusher and its wear parts, we can supply plenty of mantle models for cone crushers. Our cone crusher parts are widely used on mining, construction and metallurgical industry. We could supply most of the Sandvik, Terex, Metso crusher’s parts.

| Main material | High manganese steel (Mn13, Mn18), manganese chromium alloy (Mn13Cr2, Mn14Cr2, Mn18Cr2), etc. |

| Casting process | V method, lost mold, sodium silicate sand casting. |

| Applicable materials | Pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold mine, copper mine, etc. |

PRODUCT ADVANTAGES

Longer life

After the modification treatment, combining with the special processing techniques, the products have a service life 10-15% longer than traditional materials.

Widely used

In a wide range of fields, the new composite cone crusher mantle concave is widely used in crushing iron ore, non-ferrous metal ore, granite, quartzite, pebbles and so on.

High cost performance

The use of high manganese steel composite cone parts can reduce the investment cost of casting wear and greatly improve the return on investment.

Technical guarantee

Disappear mold casting, casting without flying edge, burr and drawing slope, casting accuracy is more accurate.

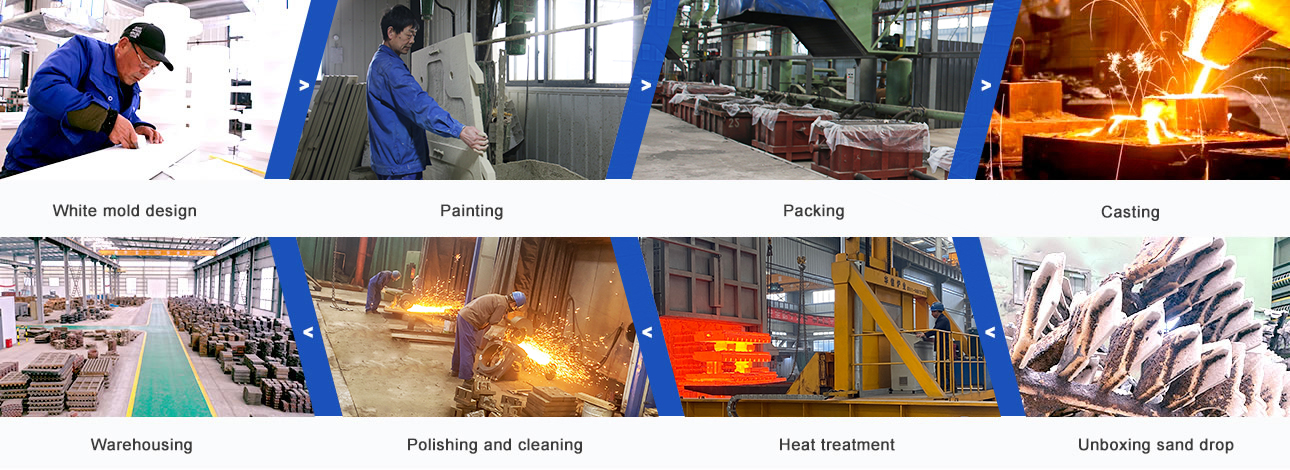

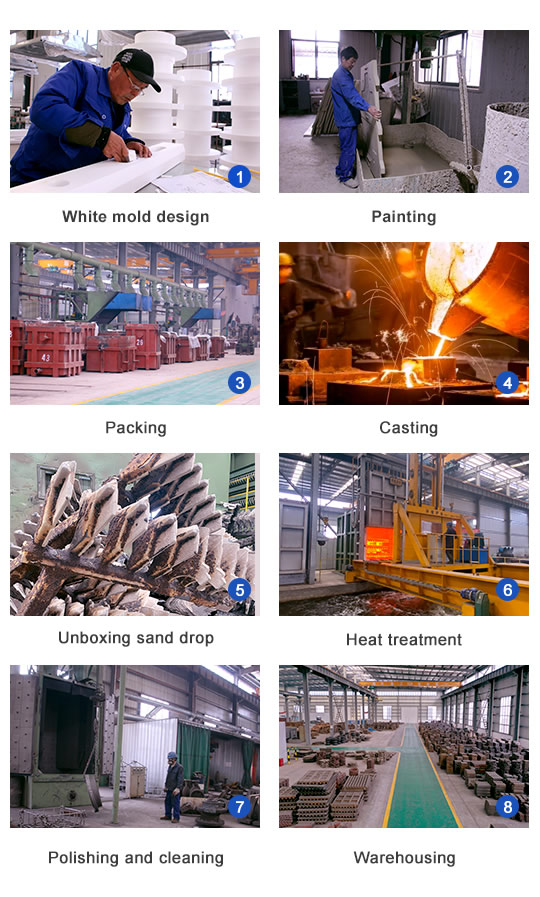

Casting process

Advaned casting process, Cost-effective crusher wearing parts

WHY CHOOSE US

Luoyang Dahua Heavy Industry is a joint-stock professional enterprise which is integrated with R&D, production, sales and service. As a high-tech enterprise, we focus on the design of crusher and grinding equipment, sand aggregate production lines, automation control schemes, civil engineering projects and also provide project installation, overall system operation and delivery.

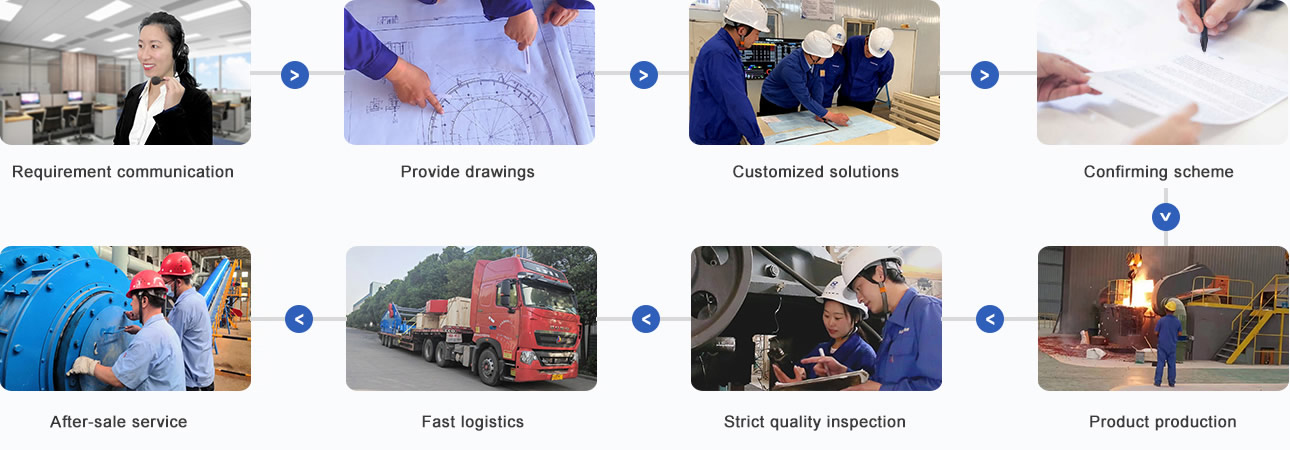

One stop customized service

Striving for excellence, One-Stone Solution to meet your requirements!