PFL Series Vertical Complex Crusher

Discharge granularity: ≤3,70-90%

Processing Capacity: 8-120(t/h)

Application Fields: it is mainly used in small and medium cement plant.

Applied material: medium soft iron ore, sandstone, blast furnace slag, coal gangue, lump coal, metallurgy solvent, etc.

Tel.: +86 13938852499 E-Mail: [email protected]

Overview

PFL series crushers are developed by our company which combined with domestic and overseas advanced technology. The machine has features such as simple structure, large ratio of crushing, low energy consumption, stable rotation, easy operation and maintenance etc.

Product Features

1.High crushing ratio: max feed size:100—200mm,discharge size: no more than 3mm and the percentage is more than 70 -90%.

2.High efficiency: the combination of this crusher and mill has boosted the output by 40% and lowered electricity consumption by 30%.

3.The multistage continuous crushing cavity formed by the optimization design of rotor and crushing cavity makes full use of energy and space and improve the performance of the machine.

4.The unique structure of feed plate is formed by the cross-distribution of feed tendons and feed plate liner. The feed tendons can be reused as feed plate liner if frayed, which greatly lifts the utilization of materials and lowers the cost.

5.Smooth running, low noise, slight vibration and good leakproofness. Easy operation, installation and maintenance.

Working Principle

After the material fall into the crushing chamber, firstly will be thrown towards the reaction liner by feed tray at high speed, then fall into the sapce between the hammerhead and reaction liner. The material will become smaller from the big size by heating, crushing , grinding of hammerhead, and finally, crushed into small granule and discharged from the crusher.

Technical Parameters

| Model | Max. Feed Size(mm) | Discharge Size(mm) | Mainshaft Speed(r/min) | Capacity(t/h) | Power(kw) |

| PFL-750Ⅲ | ≤100 | ≤3,70-90% | 800-1350 | 8 -20 | 45 |

| PFL-1000Ⅲ | ≤120 | ≤3,70-90% | 650-980 | 15-30 | 55 |

| PFL-1250Ⅲ | ≤150 | ≤3,70-90% | 510-770 | 30-45 | 90 |

| PFL-1500Ⅲ | ≤180 | ≤3,70-90% | 430-640 | 50-70 | 132 |

| PFL-1750Ⅲ | ≤200 | ≤3,70-90% | 420-540 | 70-100 | 160 |

| PFL-2000Ⅲ | ≤220 | ≤3,70-90% | 360-500 | 90-120 | 200 |

| PFL-2300Ⅲ | ≤240 | ≤3,70-90% | 330-450 | 120-160 | 250 |

| PFL-2500Ⅲ | ≤240 | ≤3,70-90% | 300-420 | 160-200 | 355 |

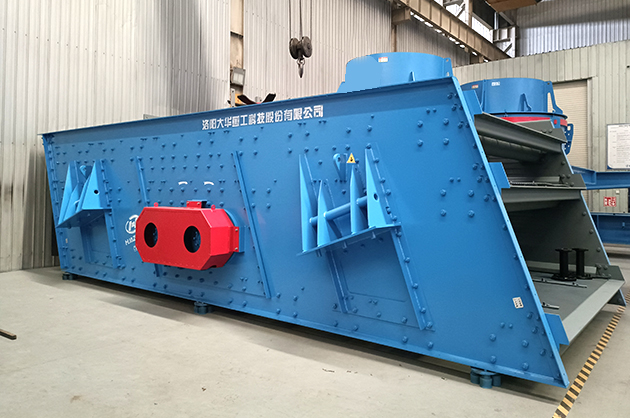

Customer Cases