Crawler Type Mobile Impact Crushing Plant

Crushing Ability: primary crushing, secondary crushing, fine crushing

Granularity: 265 – 304 mm

Application Fields: highway, high speed railway, mining, construction, metallurgy

Applied Material: various kinds of rock and ore, bituminous concrete.

Tel.: +86 13938852499 E-Mail: [email protected]

Overview

CMC series crawler type mobile impact crushing plants are utilized for crushing materials in the secondary and tertiary stages. For processing medium hard materials, the configuration form of “a feeder + an impact crusher+ a screen” is mostly adopted. The production capacity is 220 – 300 t/h.

Product Features

1. It can be utilized jointly with other mobile crushing plants and mobile screening plants.

2. The hydraulic opening and closing devices (Standard) or the specially used lifting tools (Optional) for replacement of blow bars, can provide flexible application and operation convenience.

3. The unique three-cavity vortex structure makes feed size larger, capacity larger and product shape better.

4. The standard modular cavity body lining plates, and the tooth-shaped impact plates are interchangeable, with a higher utilization rate and a longer service life.

Technical Parameters

| Equipment Model | CMC1310 | CMC1214 | ||

| Feed Hopper | Feed Capacity(t/h) | 150-300 | 150-300 | |

| Feed Hopper Volume(m³) | 4.5 | 4.5 | ||

| Feed Equipment | Model(Width mm * Length mm) | ZSW 400 * 110 | ZSW 400 * 110 | |

| Feed Height(mm) | 4010 | 4010 | ||

| Power(kW) | 15 | 15 | ||

| Crushing Equipment | Impact Crusher | PFY1310 | PFY1214 | |

| Feed Opening Width(mm) | 1000 | 1450 | ||

| Max Feed Size(mm) | 265 | 304 | ||

| Discharge Size(mm) | 30-45 | 35-45 | ||

| Capacity(t/h) | 165-200 | 220-260/300 | ||

| Power(kW) | 160 | 220/250 | ||

| Main Belt Conveyor | Model(W mm * L mm * Power kW) | 1000 * 8100 * 11 | 1000 * 8100 * 11 | |

| Discharge Belt Conveyor | Model(W mm * L mm * Power kW) | 1200 * 6400 * 11 | 1200 * 6400 * 11 | |

| Transit Belt Conveyor | Model(W mm * L mm * Power kW) | 500 * 2650 * 4 | 500 * 2650 * 4 | |

| Material Return Belt Conveyor | Model(W mm * L mm * Power kW) | 500 * 8700 * 5.5 | 500 * 8700 * 5.5 | |

| Soil Removal Side Belt Conveyor | Model(W mm * L mm * Power kW) | 650 * 4380 * 4 | 650 * 4380 * 4 | |

| Vibrating Screen | Model(W mm * L mm * Power kW) | 1500 * 3600 * 7.4 | 1500 * 3600 * 7.4 | |

| Self-Dumping Magnetic Separator | Model * Power(kW) | RCYQ1000 * 2.2 | RCYQ1000 * 2.2 | |

| Track Chassis | Walking Mode | Track-Mounted | Track- Mounted | |

| Walking Speed(km/h) | 0.8 | 0.8 | ||

| Max Climbing Angle | 20° | 20° | ||

| Integrated Machine | Driving Mode(Optional as requested) | Hydraulic Driving / Grid Power Driving | Hydraulic Driving / Grid Power Driving | |

| Omni-Hydraulic Driving | Omni-Hydraulic Driving | |||

| Engine | Model | CUMMINS | CUMMINS | |

| Power(kW) | 200-500 | 200-500 | ||

| Rotation Speed(r/min) | 1900 | 1900 | ||

| Total Weight(kg) | 45100/53700 | 43295/51795 | ||

| Transport Dimensions: L * W * H(mm) | 17150 * 3119 * 3800 | 17150 * 3119 * 3800 | ||

| Working Dimensions: L * W * H(mm) | 18130 * 3560 * 4965 | 18130 * 3560 * 4965 | ||

Note:

① The processing capacity of the crushing equipment is related to material hardness, feed size, and discharge size.

② Standard: The main belt and tail material belt equipped with folding technology, PLC+ the display control, the iron separator, and the wireless remote control.

③ Optional: Omni-hydraulic driving, the material returning system, the dust collector spraying system, the diesel injection pump, the wired remote control, the centralized lubrication system.

④ We reserve the right of final interpretation of the data, subject to change without notice.

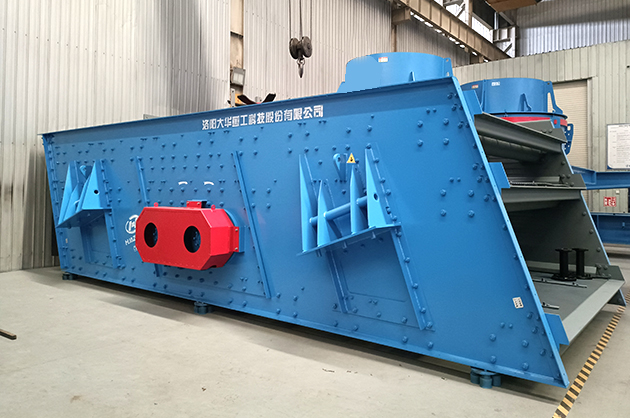

Factory Photo