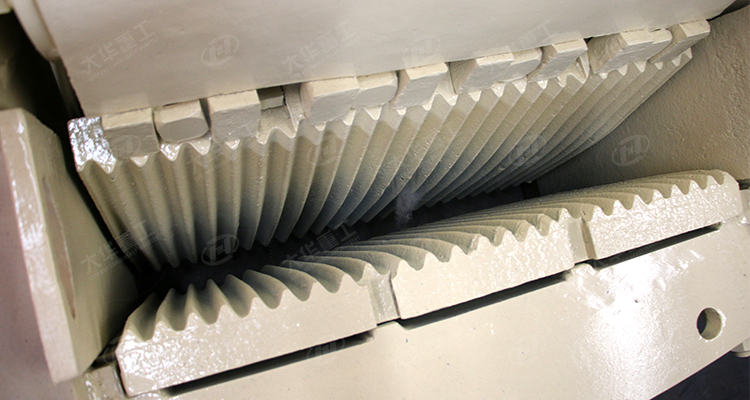

Through analysis, the main reason of jaw crusher tooth plate wearing is due to the comparatively sliding compared with tooth plate, which leads to the distortion caused by frequent squeezing between metal scrap and surface material of tooth plate. The aging of the metal material will fall off finally. The wearing procedure is:

① The material frequently crushes the chopping teeth plate. On the surface area of the tooth plate, or the metal truck part caused by squeezing, generates flaws that leads to the metal fall off directly, hence, forms the abrasive dust.

② The material frequently crushes the chopping teeth plate that cause the metal partially curled up and overturned or cracks. The cracked and curled up parts will fall out due to squeezing and impact force. Then the metal fall out together with the crushing material as the abrasive dust.

③ The material have a slightly short stroke compared with tooth plate

Due to the size difference of jaw crushers, the feeding material granularities and sharpness will have a different squeezing and impact force towards the tooth plate. The larger the machine is, the more impact force it will withstand. Despite the consideration of material squeezing force and chopping force, the impact force and bending force should also be taken into consideration. Hence large type tooth plate should use.

Through above wearing analysis we can know that, for the crusher tooth plate material, we should employ materials with high strength, high tenacity quality. At the mean time, the structure of the tooth plate should be improved to reduce the comparative movement between the material and the tooth plate, which is not only good to improve efficiency, but also improve the material service life.