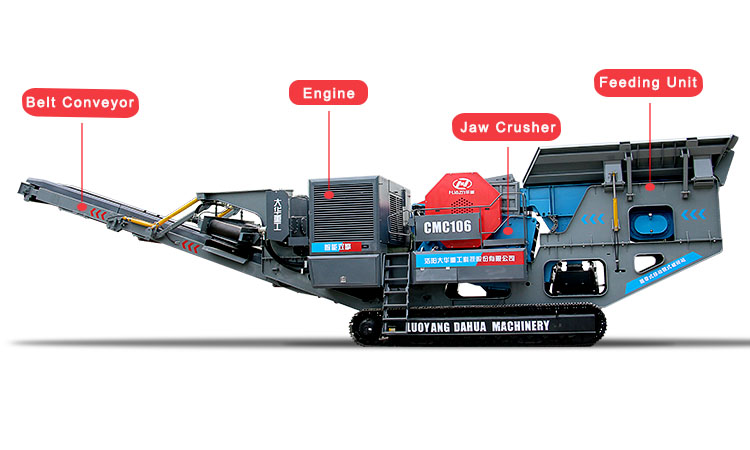

The mobile crushing plant, equipped with an integrated vehicle-mounted system, serves as a versatile crushing equipment that enables quick operation without the need for complex foundational installation. It facilitates seamless transfer between various work sites, making it particularly suitable for time-sensitive construction projects, and urgent material requirements working environments. In the following analysis, we will delve into the key components of the mobile crushing plant and their respective functionalities.

Feeding part: vibrating feeder

As the first process of the mobile crushing plant, the vibrating feeder assumes the crucial responsibility of uniformly and quantitatively supplying raw materials to the crusher. Its stability and reliability directly impact the efficiency of subsequent crushing and screening operations, serving as a fundamental basis for ensuring smooth progress throughout the entire crushing operation.

Crushing part: crusher

The crusher is undeniably the core component of the mobile crushing plant, which can be flexibly configured with jaw crushers, impact crushers, cone crushers, sand making machines, and other types of crushing equipment to meet various production requirements for coarse stone crushing, medium and fine crushing, and even sand making. Typically, a complete crushing line consists of 2 to 3 mobile crushing plants working collaboratively to accomplish stone processing tasks.

Screening part: vibrating screen

The vibrating screen is responsible for screening the crushed stone based on different specifications, ensuring that stones meeting the particle size requirements are directed to the finished product pile, while substandard stones are returned to the crusher for re-crushing until they meet the requirements.

Connecting part: belt conveyor

The belt conveyor serves as a crucial link in the mobile crushing plant, efficiently transporting crushed and screened stones to the subsequent processes, thereby ensuring the seamless operation of the entire crushing system. The conveyor can be utilized either internally or externally based on specific requirements.

In addition, the mobile crushing plant is equipped with auxiliary facilities such as a power control box, lubrication system, and control system to ensure the stable operation of the equipment. The power control box is responsible for supplying power to the entire system and controlling the start and stop of each electrical equipment. The lubrication system enhances the service life of the equipment through regular maintenance of each component. The control system acts as the central intelligence unit of the mobile crushing plant, monitoring and intelligently adjusting real-time operating statuses of each module to optimize overall performance.