There are several different types of crushing machinery for sandstone crushing, including jaw crushers, impact crushers, and cone crushers. The right one for sandstone crusher depends on the material to be crushed, the feed size, the desired product size and the capacity required. Each type of crusher has different specifications and is suitable for different types of sandstone processing. It is important to choose the right equipment for the specific needs of the sandstone processing operation.

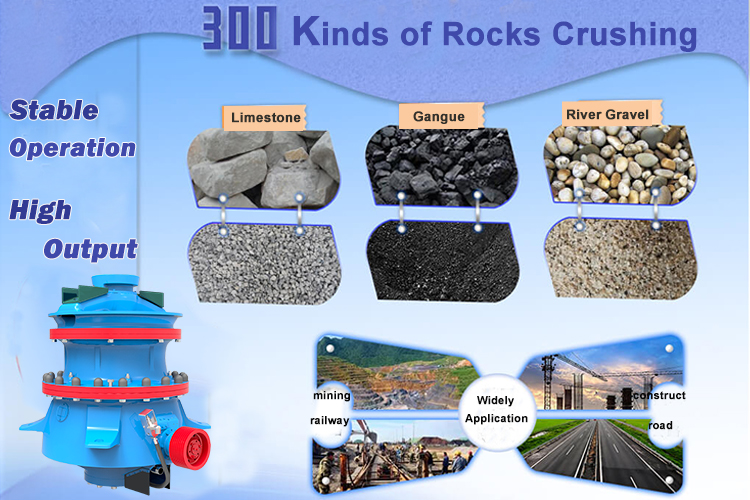

The best crusher for sandstone is the cone crusher. It is specifically designed to handle the harder materials such as sandstone. With its high crushing force, it is able to reduce large chunks of material into small and more uniform size. Additionally, the cone crusher is equipped with a lubrication system that helps prevent friction and wear on its moving parts. This makes it especially effective for applications with abrasive materials such as sandstone.

Advantages of Cone Crusher

1、Crushing process should be continuous and smooth with high production capacity.

2、The energy consumption is quite low for each ton of material.

3、The working condition is table with small shaking. It is unnecessary to install fly wheel and balancing devices.

4、Large crushing ratio (Generally 7-10).

5、Discharge opening seldom jams. It is suitable for crushing material with sheet structure. Material can be fed from any edges of the feed opening. The final product has even granularities.

Ultimately, the best crusher for sandstone depends on the specific requirements of your project. It is recommended to consult with a professional or an engineer experienced in the field of crushing and sandstone processing to determine the most suitable crusher for your needs. Luoyang Dahua is established in 1958, the company has rich experience in developing and manufacturing crusher machines. The products are sold to France, Russia, Japan, Indonesia and other 25+ countries, please contact the Online Service to get more information.