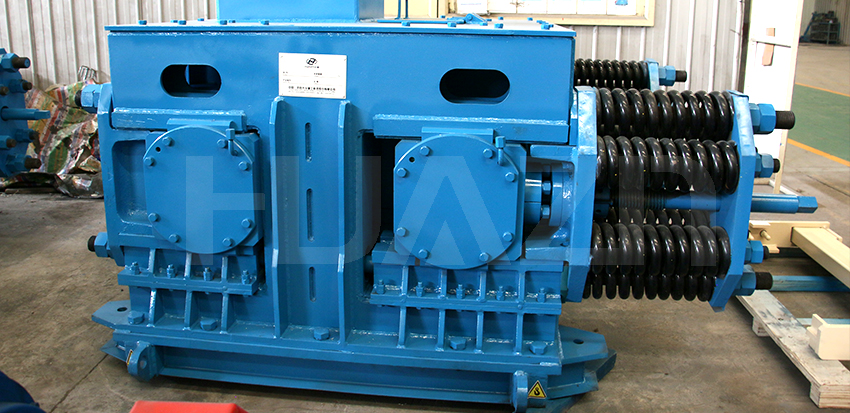

The roller crusher is mainly composed of a roller wheel, a roller wheel supporting bearing, a pressing and adjusting device and a driving device. The roller crusher is mainly classified into strong double roller crusher, four roller crusher and double tooth roller crusher. It is widely applied in cement, metallurgy, chemical, electric power, coal and other industrial sectors for the crushing of limestone, slag, coke, coal and other medium hardness materials.

Cement industry: Roller crusher is often used to break limestone, cement clinker, sandstone, coal and gypsum and other materials to improve work efficiency.

Chemical industry: Suitable for coal, coal gangue, coke, pyrite, lapis lazuli, calcium carbide and other materials crushing, simple operation, reasonable design.

Mining industry: It can be used for crushing iron ore, quartz stone, gold ore, feldspar, swallow stone and other materials to meet the strict requirements of ore production.

Working principle and characteristics of roller crusher

1, The tooth roller crusher mainly uses special wear-resistant tooth roller to split and break the material (traditional tooth roller crusher uses low-speed extrusion crushing) at high-speed rotation, forming a high productivity mechanism.

2, The driving mechanism is composed of two electric motors, driving the roller to the grooved wheel by the triangular belt, and rotating in the relative direction of motion. When the material is broken, the material is crushed by rolling through the roller from the feed port, and the finished product is discharged from the bottom frame.

3, Simple structure, easy maintenance, and low operating cost.

4, The clearance of the discharge port is adjustable, which can ensure the discharge particle size according to user needs.