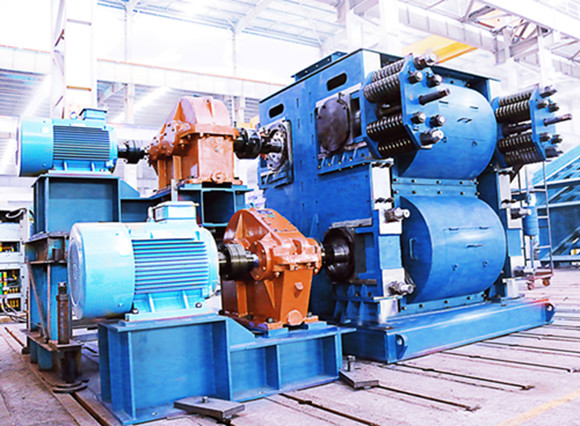

1. Non-crushed materials should be taken out before they get into the hopper. Iron mover or any other methods can be put to stop them.

2. The safety adjustment springs must have enough compressive press during operation, to ensure the product granularity and output.

3. The materials while feeding can not be too big for avoiding wearing of the roller husk.

4. Make sure the central line of roller shaft be parallel during operation.

5. The even feeding must be assured to avoid wearing of roller parts.

6. Regularly inspect the final granularity.

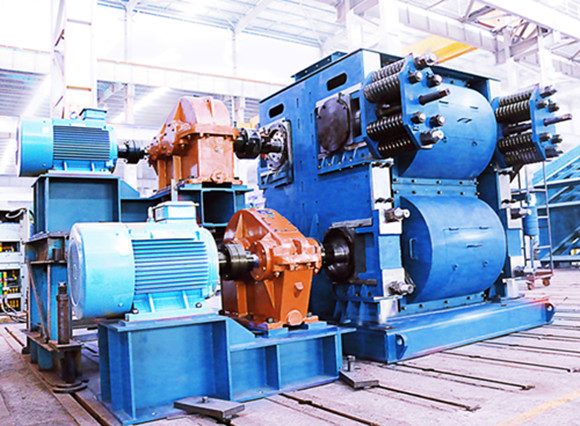

Our company has rich experience in manufacturing crushing machines with low price, good performance and win great recognition and trust from the customer, if you are interested in any of them, please contact with us:

Tel: 0086-379-62669906

Email: [email protected], [email protected]